Six Sigma is highly recommended for organizations that are highly structured and use a hierarchical model of leadership. Lean is more flexible and can be used in an autonomous organization to enhance collaboration. Besides above two methods, other notable tools for applying six sigma are DOE (Design of Experiments), FMEA (Failure Mode Effects Analysis), Pugh Matrix (Decision Matrix Method) etc. Yes, many of the universities and organizations that offer Six Sigma certification have both classroom and online offerings. The team works from there to implement changes that will improve system performance.

Not Suitable for Every Business

After this venture, Motorola further applied the principle successfully to many other areas of their business like for improvement of human resource, management of operational cycle and cost cuttings. Daniel Raymond, a project manager with over 20 years of experience, is the former CEO of a successful software company called Websystems. Throughout his career, Daniel has consistently demonstrated a commitment to excellence and a passion for empowering teams to achieve their goals. A process that can aid with the implementation of Lean Six Sigma is Advanced Planning and Scheduling (APS) Software. APS Software is a cutting edge technology system that enables manufacturers to have thorough insight into their overall operation and improve their operation through bottleneck elimination and process improvement. APS can easily be integrated into manufacturing operations that are seeking to enhance efficiency within their operation and ultimately cut costs and improve profitability.

Overemphasis on defect reduction

While their knowledge and skills are valuable, an overreliance on these experts can create a dependency and hinder the organisation’s ability to sustain improvement efforts in the long run. We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Top 10 Cons or Disadvantages of Using Six Sigma Certification

These barriers are hard to predict as this will not be the same for every business. In addition, focusing on the development will have more such problems arising, and all of them require proper strategies to solve effectively. With Six Sigma, the feedback that employees get from their bosses can also lead to a greater sense of unity. Six Sigma has a proven track record of value-added processes and high-quality production. According to Toyota, the seven kinds of waste in Lean manufacturing are inventory, waiting for motion over-processing, overproduction, defects, and transport. Six Sigma has become a widely used quality-improvement methodology in both the private and public sectors.

All About Six Sigma Certification: 6 Things To Consider!

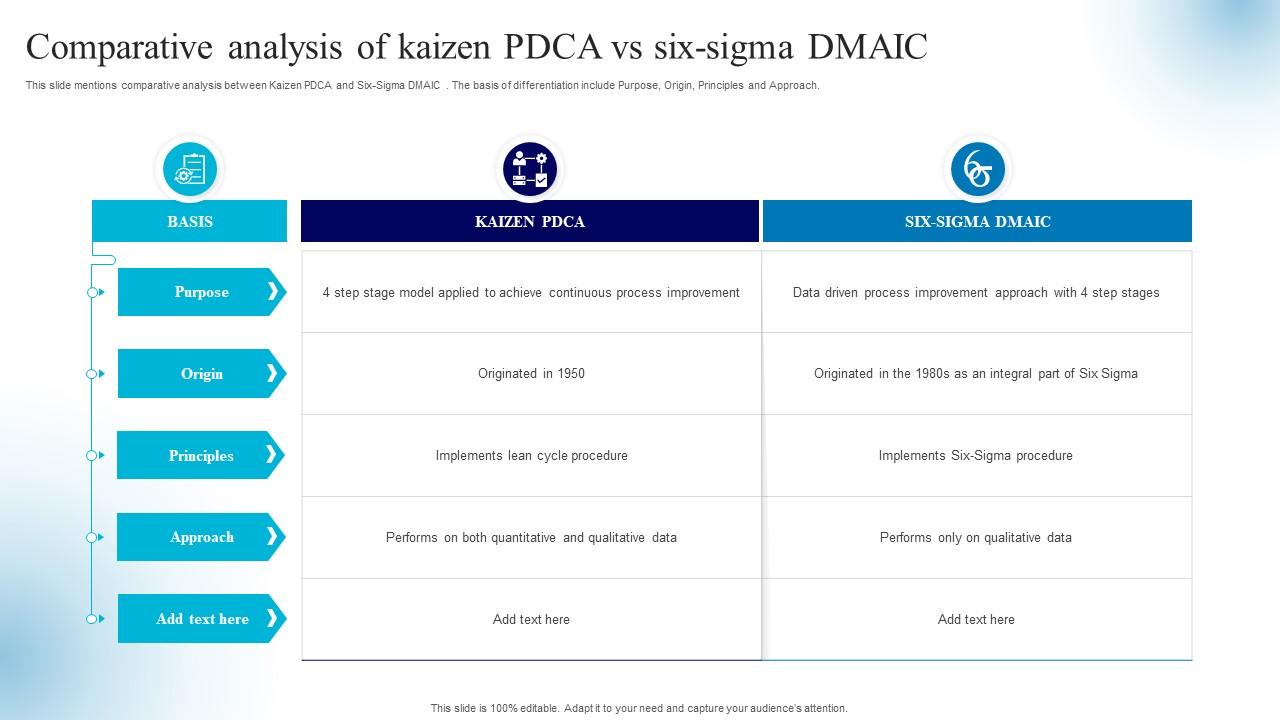

This resistance isn’t just about nostalgia or stubbornness; it’s about fear of the unknown, concerns about adaptability, and worries about potential redundancies. This friction, if not managed correctly, can lead to decreased morale, lack of faith in the system, and even active pushback against Six Sigma initiatives. Many experts argue that while it offers numerous benefits, there are also considerable disadvantages that companies should be wary of before fully embracing Six Sigma. The Six Sigma method uses a step-by-step approach called DMAIC, an acronym that stands for Define, Measure, Analyze, Improve, and Control. According to Six Sigma adherents, a business may solve any seemingly unsolvable problem by following these five steps.

- These principles are essential in reducing backlog when responding to customer requirements.

- This commitment to continuous improvement leads to sustainable long-term results and ensures that the organisation stays ahead of its competitors.

- Now a standard business methodology, this approach started as a revolutionary manufacturing process in the 1950s.

It may also be utilized to optimize supply chain processes and increase customer satisfaction. The benefits of utilizing Six Sigma will go beyond simple-problem solving and considering the entire production process from raw materials to the end product as opposed to only the end product. The company first established standards for all of its hardware and software to create a baseline measurement for detecting defects.

As a result of Six Sigma, Microsoft says it improved the availability of its servers, boosted productivity, and increased customer satisfaction. Six Sigma quality is achieved when long-term defect levels are below 3.4 defects per million opportunities (DPMO). Six Sigma is based on the idea that all business processes can be measured and optimized. Six Sigma also does not technically allow for the introduction of new tools or methods, even when they could be beneficial. Since Six Sigma generally requires total dedication across all teams, it’s difficult to use or experiment with other process methodologies for other areas of the organization. Originally developed for manufacturing, Six Sigma can now be found across many industries.

Lean is a systematic approach to minimizing waste within manufacturing systems without sacrificing productivity. It focuses on identifying and eliminating non-value-added activities (or “muda” in Japanese) to streamline processes and improve what is accounts receivable days formula and calculation efficiency. Lean principles are based on the Toyota Production System (TPS) and have been widely adopted across various industries. Six Sigma is also a set of tools and techniques that organizations use to improve business processes.